Define the basics…

A ‘PCB’ or Printed Circuit Board connects electrical components on a conductive track or between pads on the board. Some devices hold more than one PCB and will utilise a variety of equipment to build a connection between the boards.

PCB connectors are mounted on the PCB and are typically used to transfer signals or power from one PCB to another, or to transfer to or from the PCB from another source within the unit. Connectors provide an easy method of Design for Manufacture, as the PCBs are not hard-wired to each other and can be assembled later in a production process.

There are different types of PCB connectors that have different roles to play on the board. The final application will determine the Size, Weight and Power (SWaP) properties of the connectors used in the PCB design. For example, a connector used within a mobile phone will need to be smaller and lighter than a connector used within a car to withstand high current.

PCB Connector Orientations

The term PCB Connector refers to a basic multi-pin connection system, typically in a rectangular layout. A mating pair of PCB Connectors will either be for board-to-board connections or cable-to-board (also known as wire-to-board).

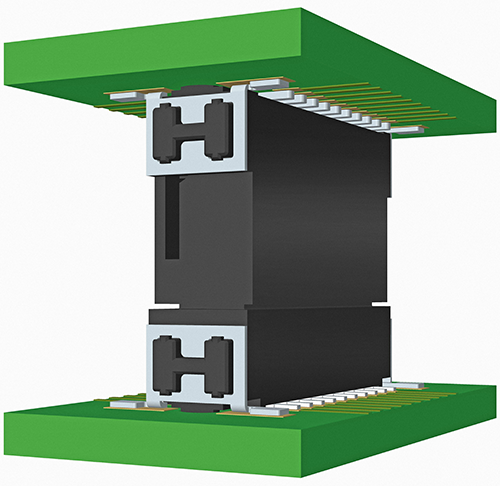

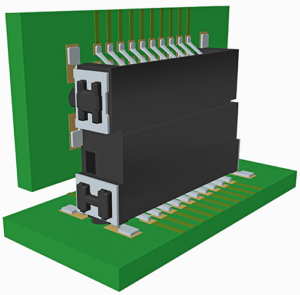

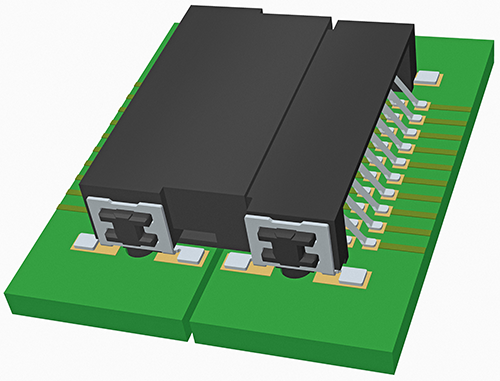

Board-to-board connector layouts can provide a range of PCB connection orientations, all based on 90 degree increments:

Parallel or mezzanine – both connectors are vertical orientation;

90 Degree, Right Angle, Motherboard to Daughterboard – one connector is vertical, one is horizontal;

180 Degree, Coplanar, Edge-to-Edge – both connectors are horizontal orientation.

Other names for PCB Connectors

PCB Connectors can also be known as PCB Interconnects. Specific terms are also used for the two mating sides of the connection.

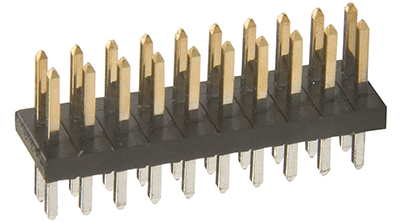

Male PCB Connectors are often referred to as Pin Headers, as they are simply rows of pins.

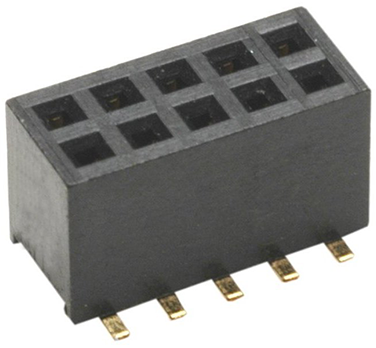

Female PCB Connectors can be called Sockets, Receptacles, or sometimes even Header Receptacle

Types of PCB Connectors

There is a wide variety of PCB connectors available on the market, all designed to meet the needs of specific applications. For example, some connectors specialise in resisting vibration and shock from environmental factors, and provide stability under stressful conditions. Other connector types are much more delicate for highly sensitive applications, or of a more standard, economical design for industrial production and manufacturing.

For the more stressful environmental conditions, High-Reliability connectors are key to ensuring that electrical connectivity is not disrupted. For more static equipment, Pin Header and Socket designs of PCB Connector are perfectly sufficient for the task.